Ports of Auckland Limited (POAL) is a busy workplace. Serving New Zealand’s biggest city, the number of containers they handle increases every year, but the port can no longer keep reclaiming land to cater for this growth. Increasingly the port is looking to technology to create more capacity. Last year, they announced their decision to start work on partially automating their straddle carriers, the machines which move containers around in the terminal. With this decision came a herculean task—to modify the existing straddles to work with the 27 new robotic carriers due to start arriving in December 2017. These new robotic straddles are taller and able to stack containers higher, but this means they don’t fit into the port’s existing engineering workshops. That’s where SmartShelters stepped in.

Proudly New Zealand-made

SmartShelters is a part of the CW (Cairns & Woodward) Group Limited, which has more than 100 years of expertise in manufacturing and supplying steel-framed fabric clad structures in New Zealand and globally. CW’s history goes back to when they first supplied military canvas products during the First World War. Over the years, the company has grown to provide weather protection solutions for industrial, agricultural, and commercial use.

The Ports of Auckland project

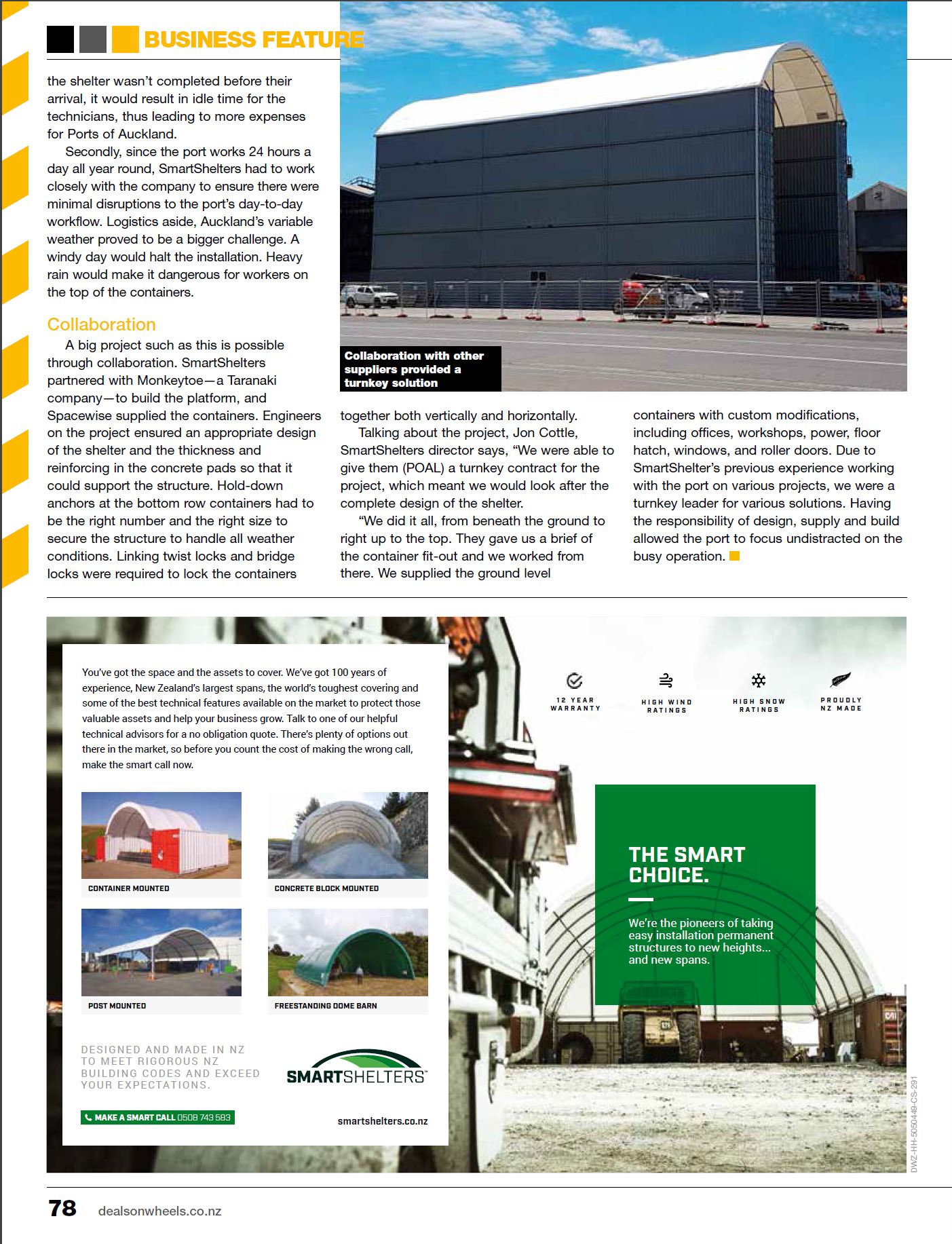

As part of the Ports of Auckland project, SmartShelters was tasked with building a container shelter for the new 16-metre tall robotic straddle carriers that work round the clock. The team at SmartShelters came up with a design where the shelter would have an H-shape footprint, thus enabling work on two straddles simultaneously from a mid-point platform. The SmartShelters structure is 17.2 metres wide and 36.6 metres long with a centre height of 19.8 metres. It is mounted on a stack of 40-foot containers five high on each side and across the middle of the H, four containers high, on which an aluminium work platform was mounted, 12 metres up to access the upper level of the straddles.

Contact SmartShelters today to get started on your container shelter project.

Nearly there! Drone image captured moments before installing the fabric roof.

Challenges

The project was planned to take around six weeks but was completed in just five. However, it came with its challenges. For one, SmartShelters was racing against the clock. Technicians from Germany were due to arrive in Auckland to assemble the new machines. If the shelter wasn’t completed before their arrival, it would result in idle time for the technicians, thus leading to more expenses for Ports of Auckland. Secondly, since the port works 24 hours a day all year round, SmartShelters had to work closely with the company to ensure there were minimal disruptions to the port’s day-to-day workflow. Logistics aside, Auckland’s variable weather proved to be a bigger challenge. A windy day would halt the installation. Heavy rain would make it dangerous for workers on the top of the containers.

Collaboration

A big project such as this is possible through collaboration. SmartShelters partnered with Monkeytoe—a Taranaki company—to build the platform, and Spacewise supplied the containers. Engineers on the project ensured an appropriate design of the shelter, the thickness and reinforcing in the concrete pads so that it could support the structure. Hold-down anchors at the bottom row containers had to be the right number and the right size to secure the structure to handle all weather conditions. Linking twist locks and bridge locks were required to lock the containers together both vertically and horizontally. Talking about the project, Jon Cottle, SmartShelters director says, “We were able to give them (POAL) a turnkey contract for the project, which meant we would look after the complete design of the shelter. We did it all, from beneath the ground to right up to the top. They gave us a brief of the container fit-out and we worked from there. We supplied the ground level containers with custom modifications, including offices, workshops, power, floor hatch, windows, and roller doors. Due to SmartShelter’s previous experience working with the port on various projects, we were a turnkey leader for various solutions. Having the responsibility of design, supply and build allowed the port to focus undistracted on the busy operation.”

Leave A Comment

You must be logged in to post a comment.